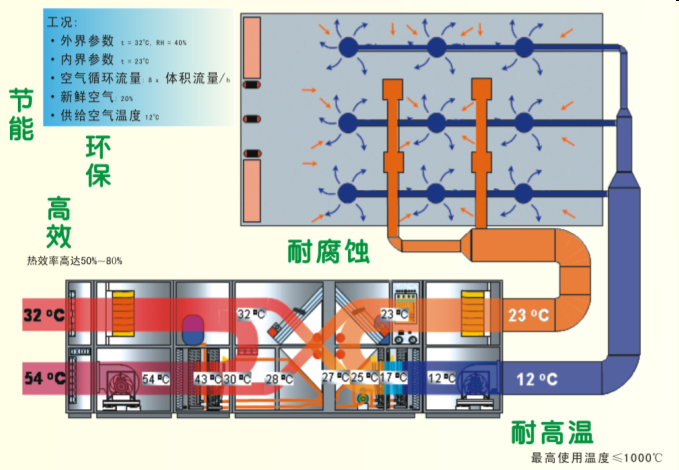

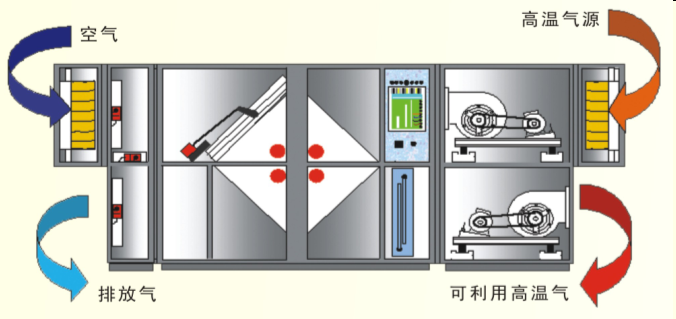

Principle and structure of gas gas heat exchanger:

In the fixed frame of the steel structure, each heat transfer plate is formed by coincidence of 90 degrees of heat. The smoke passes through the corrugated plate in horizontal direction, and the air passes through the corrugated plate in the vertical direction.The gas - air heat exchanger has the advantages of compact structure, wide range of material selection, less fouling and less maintenance. It has the advantages of elastic sealing and non welding of the heat transfer surface.The utility model has the advantages of good energy saving performance, corrosion resistance, or stainless steel, etc. the heat efficiency of the gas air heat exchanger is as high as 50%~80%, and the maximum service temperature is up to 1000 DEG C.The efficiency of the industrial furnace can be increased by 5%~10%, and the investment recovery period is short, and the total investment can be recovered in generally 1 to 2 years.

Wide use of gas - air heat exchangers:

The utility model is most suitable for the recovery of heat from flue gases of various industrial furnaces and kilns, and the recovered heat energy can be used for heating, supporting new air, heating water or other liquid media or for other purposes. In the food, paper, petrochemical, power, steel, smelting and other industrial range, the internal heat recovery system can also use the gas - air heat exchanger.

020-86099023 | 86098701 | 86098693

020-86097959 | 86096463 | 86099617

24-hour Serivce Tel:02086099023

24-hour Serivce Tel:02086099023